Capsules / Tablets

Syrup & Suspensions

Powders & Granules

Energy Drink

Sachets

Drops

Sanitizer & HandWash

Welcome To

CASCA REMEDIES PVT .LTD.

With the opening of Indian Economy to the world, Indian Pharmaceutical Industry, by virtue of its inherent strength of large pool of scientific community, massive manpower and cheap labor, was poised to become Pharma Super Power. In order to achieve this goal in global pharma market, it was imperative that Indian companies upgrade technology, adopt stringent quality control procedures and evolve a culture of living up to strict delivery schedules. In an effort to produce quality medicines at affordable prices, most modern plant and machinery backed with highly skilled team of professionals have been put in place at CASCA REMEDIES PVT. LTD., which was incorporated in 1988 in Ambala Cantt, and since then we have grown from a little two man operation to fully functional state-of-the-art manufacturing facilities, using latest machinery, equipment’s and testing instruments. Present manufacturing facility meets the strict Schedule – M, GMP & an ISO 9001:2015 norms.

Casca Remedies Pvt . Ltd. Leading Top Pharma Manufacturing Company In India .We deliver quality medicines at affordable prices and holds the utmost place in the industry as the leading third party manufacturing pharma companies.

Casca remedies stands above as the best third-party manufacturing to export medicine across as well as the outside country in an international market. For reputed pharmaceutical players, Casca Remedies provides a third-party manufacturing facility. In the pharmaceutical industry, when it comes to outsourcing, we ensure to make this activity easy & flexible by performing the following activities that include:

- Provide contract manufacturing of Tablets, Capsule Manufacturers, Injection Manufacturers and Syrup Manufacturers.

- Depending on your needs, our services include purchasing raw materials, production, packaging, and quality control.

- We are able to integrate perfectly into your supply chain, through this flexible approach.

- Top Tablet Manufacturers in India, Third Party Manufacturing of Capsules, Third Party Manufacturing of Injections, Third Party Manufacturing of Syrups

Benefits of Pharma Third Party Manufacturing

If you are the one who is searching about what are the benefits of investing in outsourcing companies then your search is finished here. Here below we have listed a few of the benefits of investing in this area:

You do not have to spend your time and money on the production plant, transport facility, raw materials, hiring extra labor, storehouses, and many other resources. As saving time and money is the crucial benefit that every third party company offers.

The company is able to provide the appropriate transportation, and labor according to the market. We work with flexibility and ensure to deliver the best in all the possible aspects.

There will be great market expansion as these companies do have massive links in the market which helps to raise the business and elevate the earnings section.

Our Clients

WHAT DOCUMENTS ARE REQUIRED TO DEAL WITH THIRD-PARTY MANUFACTURER?

- Agreement for Manufacturing.

- Profile of the Company including the - Name, and address Of all directors, Stating telephone number both official and residential Partners or Proprietor)

- Certificate for Non-Resemblance

- An attested copy of the Drug Licenses is needed to be submitted

- Attested a copy of GST Registration Certificates.

- PAN card, Aadhaar Card, GST Registration

- An attested copy of the Drug Licenses is needed to be submitted.

- For Limited companies, copy of a Resolution for Authorized Signatory.

- Partnership deed of the Partnership firm.

- Affidavit for Proprietorship firm.

- In the case of Pvt. Ltd or limited Company, the Memorandum & Articles of Association.

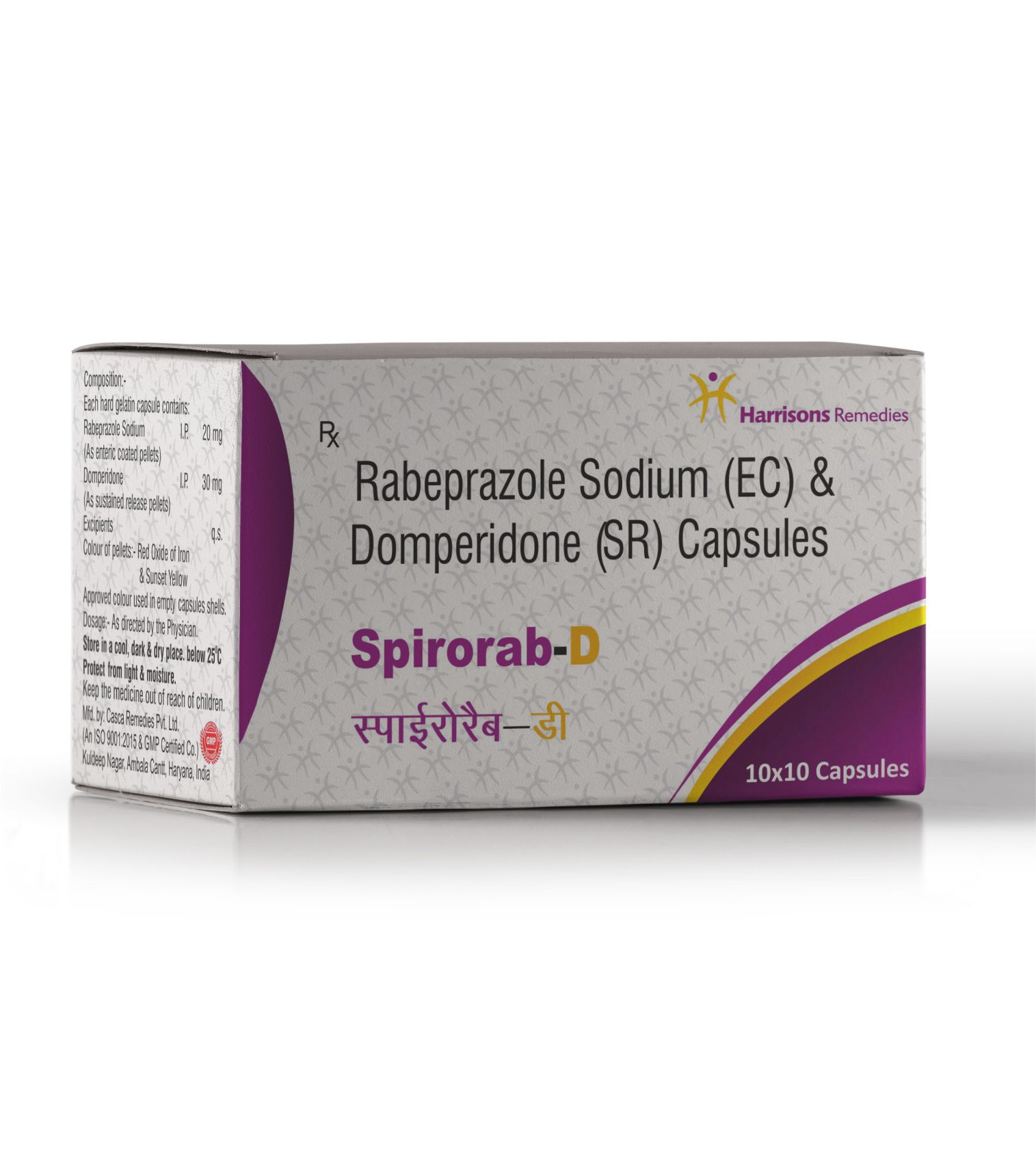

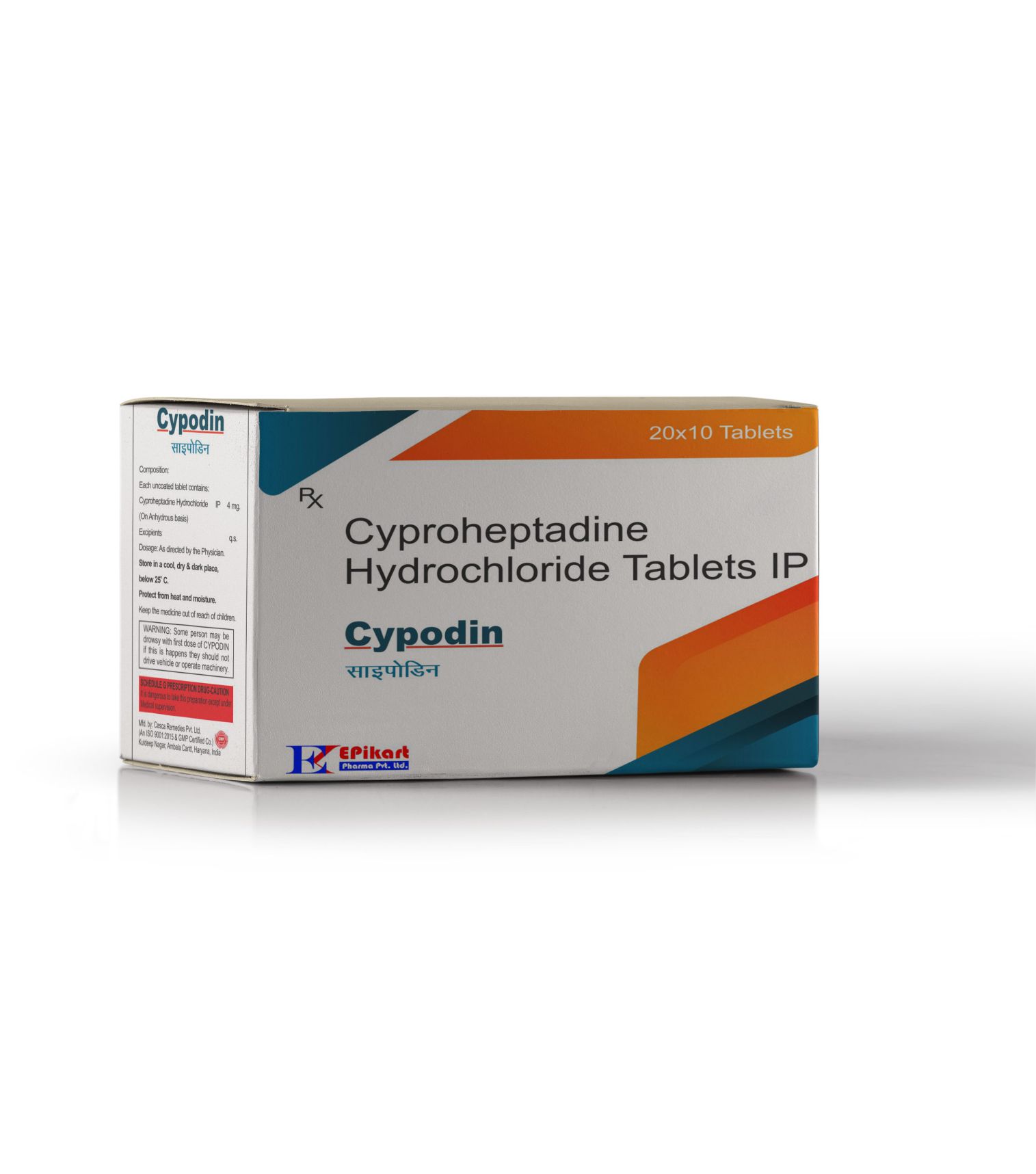

OUR PRODUCT DESIGN

6 STEPS FOR THIRD-PARTY MANUFACTURING

SELECT PRODUCTS AND REQUEST FOR RATES

Select your desired products which you wish to manufacture with your own brand names Shortlist a list of potential manufacturers online, referral, etc. Send them email/call them to request for their quotation which should include Product Cost, expenses related to product manufacturing, securities, the minimum quantity of the delivery schedule.

FINALIZING ORDER QUANTITY AND COMPOSITION

You should finalize the order quantity of the selected product. While concluding the order quantity you have to keep in mina minimum order quantities for the composition as mentioned by the manufacturer MOQ can be 500 boxes For syrup 2500 Bottles For Injections - 2000 Units

RAISING PURCHASE ORDER

After finalizing composition and order quantities for contract manufacturing. You should raise a purchase order to the selected manufacturer. You should also request the manufacturer to confirm your products, After confirmation. a partial advance should be deposited to initiate the process.

FINALIZE ARTWORK

After submission of advance, you should complete all the registration formalities as asked by the Manufacturer. You should finalize your design artwork as soon as possible. Key Points to check while finalizing Artwork Check Brand Name on carton & foil - Check Packing details. Composition, Manufacturing details - Check Design & Color combination Check Marketed By company name, logo & address on carton & foil

SUBMISSION OF DOCUMENTS

Company profile , Director's documents (Aadhar Card and Pan Card) , Copy of Resolution for Authorized Signatory to Deal , Drug Licenses , Sales Tax/TIN Registration Certificates , Agreement for Manufacturing , Certificate for Non-resemblance

DELIVERY OF GOODS

After goods are manufactured, you will receive a quotation mentioning the details of product manufacture and the balance amount to be deposited. Goods will then be dispatched through your desired transporter after submission of documents & clearance of accounts.

Contact Us For Third Party Manufacturing

Get Product List & Price List